One of the most ovious scope/field of automation and robotizing is movement and sorting of materials.

For many production companies nowadays it is a challenge to find human workforce to handle the logistics of products with various sizes, shapes and cycle times. For them, automation is an efficient investment. Besides, implementation of a robotic system in this field is fairly simple since it probably does not require micro-millimeter-scale accuracy.

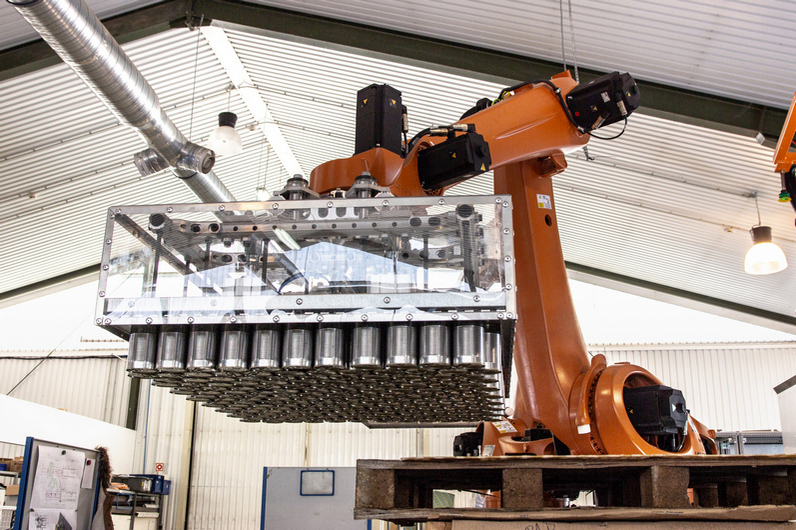

Robot manufacturers also realized the potential of the production sector – and a few of them have already developed special palletizing robot arms, which, unlike the traditional 6-axis robots, operate with 4 axes only – though without lacking any thorough technological background.

Automation prefers exactness, it is easier to move and orient a box. However, technology today offers excellent solutions for the optimum handling of objects with other dimensions like sacks or bags.

Key areas to pay attention to:

- material, size (of packaging), variance

- geometry (and its variance)

- weight (and its variance)

- packaging material consumption

- cycle time

- positioning

- layout

- stack size and weight

- buffering

- material flow (input, output)

- available space

- approach

- environmental conditions (dust, moisture, heat, etc.)

- manual and automatic modes

The following photos illustrate some characteristic solutions of Robot-X.

We’re ready to help you if you are about to invest in a similar development or have any questions regarding these applications.